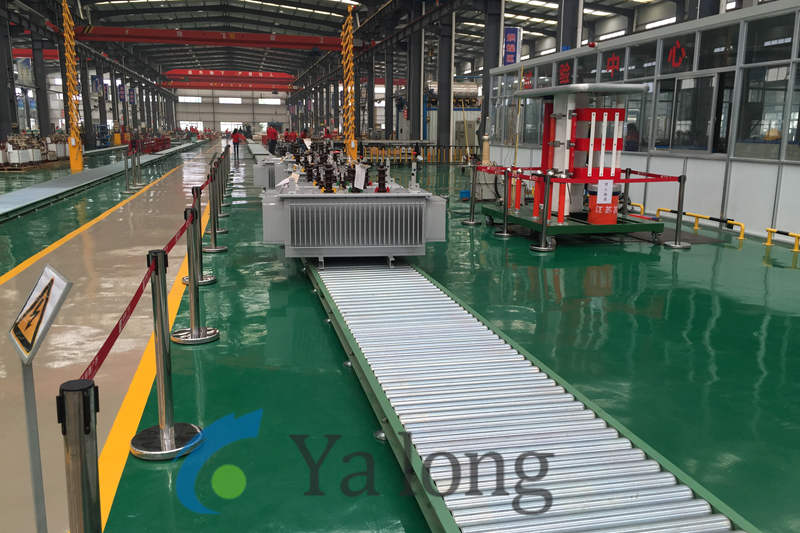

Transformer Assembly Line (TAL) Functional Summary

I. Conveying System Functions

Roller Conveying Line (RCL)

Structure: Metal rollers

Function: Transfers large transformer shells/finished products

Compatibility: Forklift/crane-assisted loading/unloading

Plate-Chain Conveying Line (PCCL)

Structure: Heavy-duty metal chains/plates (ton-level capacity)

Function: Transfers cores/active parts

Application: Body assembly & final assembly processes

Belt Conveying Line (BCL)

Traits: Flexible/low-noise

Function: Feeds/sorts small parts (silicon steel sheets/enameled wires)

Double-Speed Chain Line (DSCL)

Mechanism: "Fast-slow switching" chain plates

Function: Precision positioning (e.g., winding placement on body)

II. Core Advantages

Process Automation

AGVs replace roller tables for flexible path planning

AI visual inspection (winding tightness/insulation defects)

Automatic defect sorting (zero manual intervention)

↓ Process waiting time

Equipment Collaboration

Conveyor ↔ Winding machine/welding robot signal linkage

"Completion signal" triggers automatic coil transfer

Multi-Product Adaptability

Adjustable positioning stops

Rail change mechanisms

Programmable speed settings

Supports 10kV/35kV transformer rapid switch