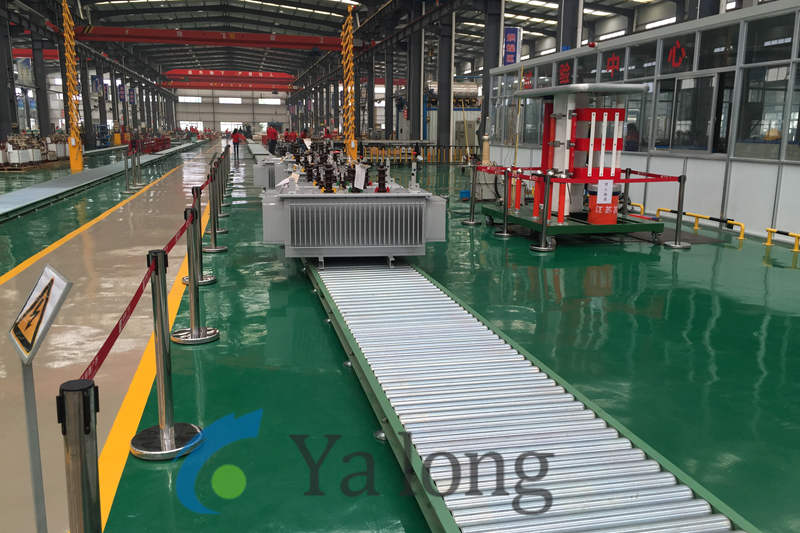

The transformer assembly line (transmission line) is a crucial logistics and production collaborative system in the transformer manufacturing process. It is mainly used to realize the automated transfer of parts, semi-finished products and finished products between various processes in the transformer production process.

Different production line functions:

1. Roller conveying line: It is made up of metal rollers and conveys materials through the rotation of the rollers. It is suitable for large transformer shells, finished products, etc., and can be used with forklifts or cranes to assist in loading and unloading.

2. Plate and chain conveying line: It is composed of metal chains or chain plates with strong carrying capacity (up to several tons). It is suitable for heavy-duty semi-finished products (such as iron cores and body) and is often used in body assembly and final assembly and other processes.

3. Belt conveying line: It has good flexibility and low noise. It is mostly used for feeding and sorting small transformers or parts (such as silicon steel sheets and enameled wires).

4. Double-speed chain conveying line: "fast and slow switching" is realized through the double-speed chain plate (such as fast-forwarding to the workstation and then decelerating for positioning), which is suitable for assembly processes that require precise positioning (such as setting windings on the body).

Core advantages of transformer assembly line:

1. Process connection automation: Introduce AGV (Automatic Guided Vehicle) to replace traditional roller tables to achieve flexible path planning, combine AI visual inspection (such as winding tightness, insulation layer defects) to judge quality online and automatically sort defective products, without the need for manual participation throughout the process. Reduce process waiting time.

2. Collaborative operation of process equipment: The conveying line is linked with the winding machine, welding robot and other equipment through signal interaction. When the winding machine completes winding the coil, it sends a "completion signal", and the conveying line automatically transfers the coil to the next station;

3. Flexible adaptation to multiple varieties of production: Through adjustable positioning stops, rail change mechanisms and programmable speed, the transmission line can quickly switch the transmission parameters of different types of transformers (such as 10kV distribution transformers and 35 kV power transformers).