Inverter Assembly Line (IAL) Technical Overview

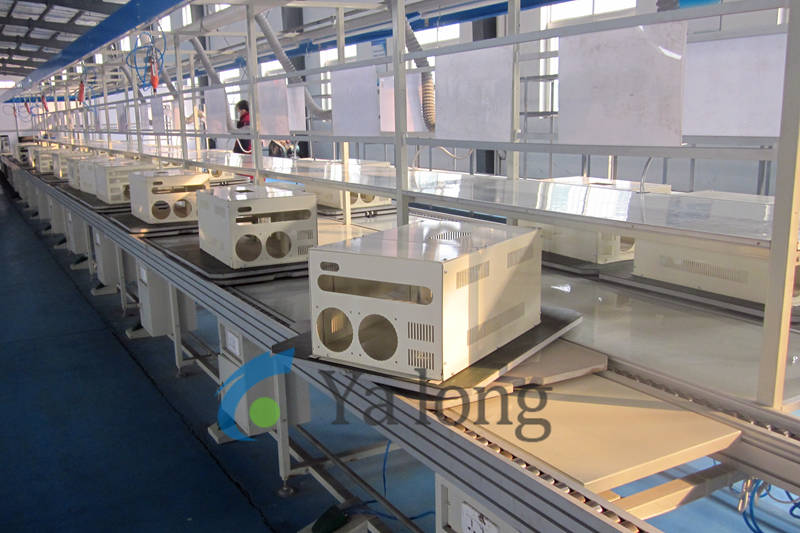

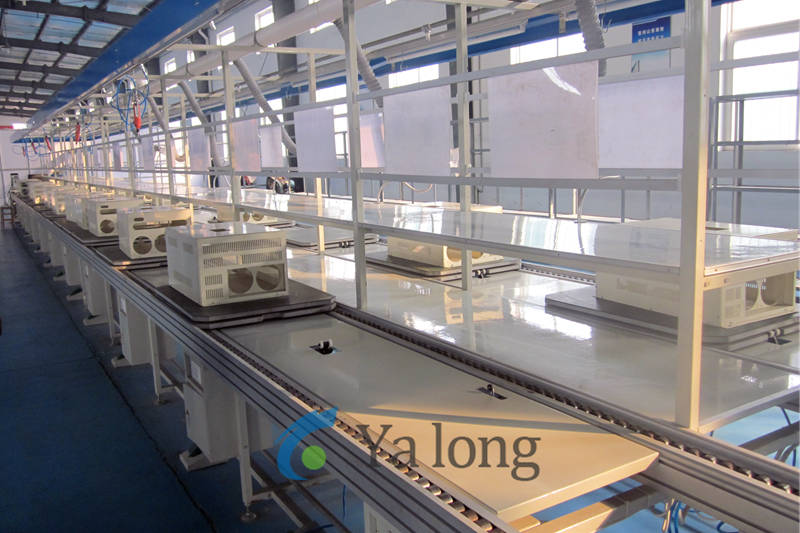

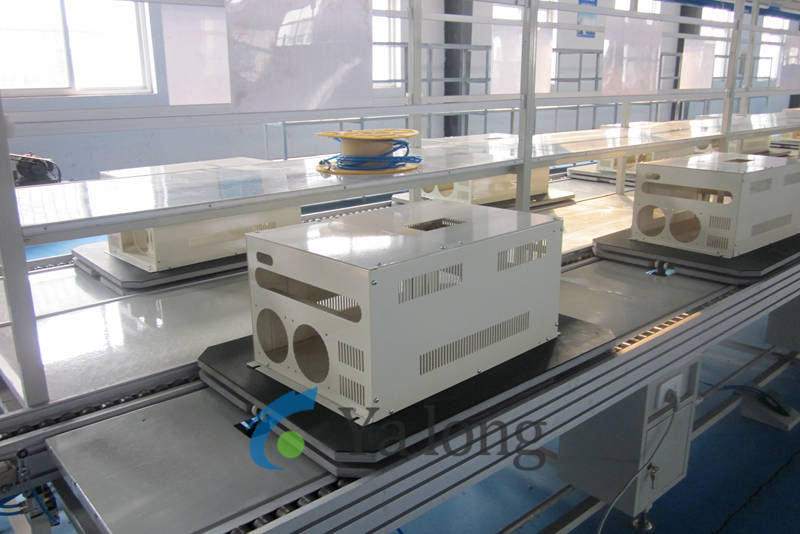

I. Core Conveying System

Continuous Belt Conveyor Line (CBCL): Smooth product flow, low friction

Double-Speed Chain Line (DSCL): Fast transfer + slow positioning (precision ±0.5mm)

Function: Avoid stagnation, ↑ rhythm efficiency by 30%

II. Product Scope & Applications

Products:

Household/Commercial inverters

Energy Storage Converters (PCS)

Applications:

PV/Wind Power Generation

EV Charging Systems

Grid Energy Storage (ESS)

III. Automated Production Process

Robotic Assembly (ROB):

6-axis robots for component placement/welding (accuracy ±0.1mm)

Automated screw fastening (torque ±3%)

Functional Validation Testing (FVT):

Input/output stability test (±1% voltage tolerance)

Efficiency curve verification (EN 50530 compliant)

Power curve analysis (Sandia Model)

EMC Compliance:

Surge immunity test (±4kV)

Radiated emissions screening (≤30dBμV/m)

IV. Hybrid Production Model

Automated Transport (ATC): CBCL/DSCL material flow

Manual Precision Control (MPC): Human oversight for critical alignments

Intelligent Monitoring System (IMS):

Real-time OEE tracking

Defect auto-classification (AI vision)

MES data integration