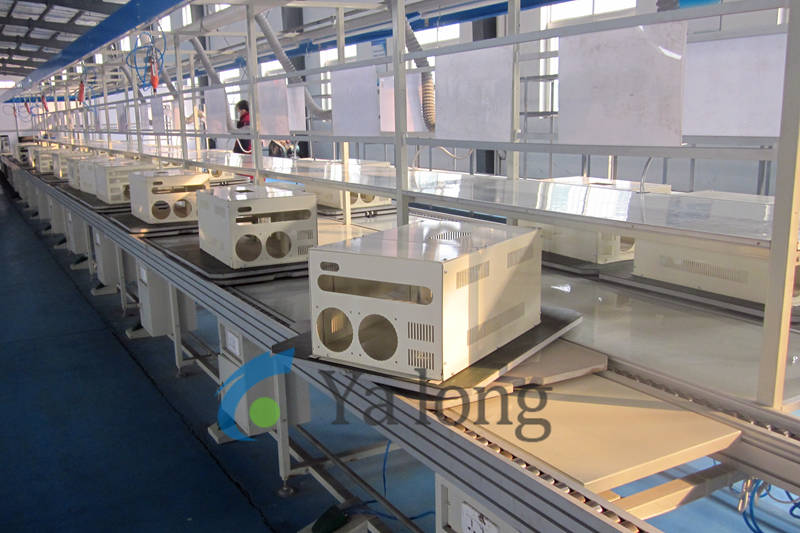

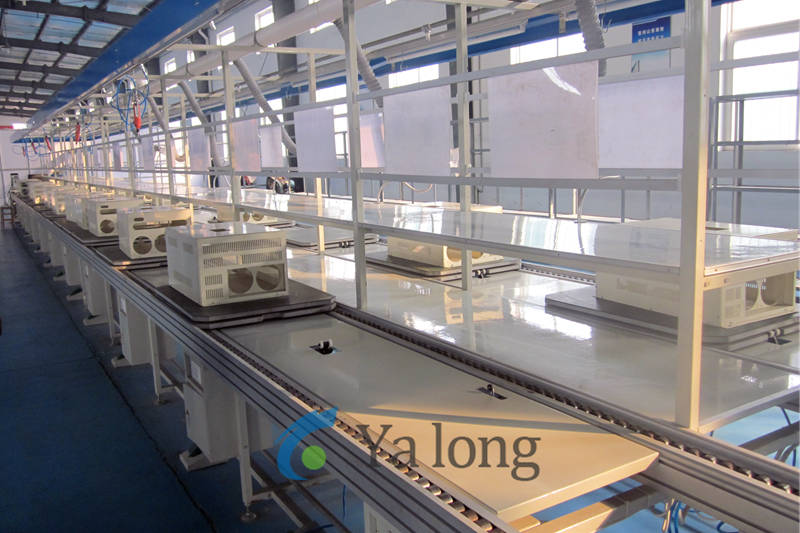

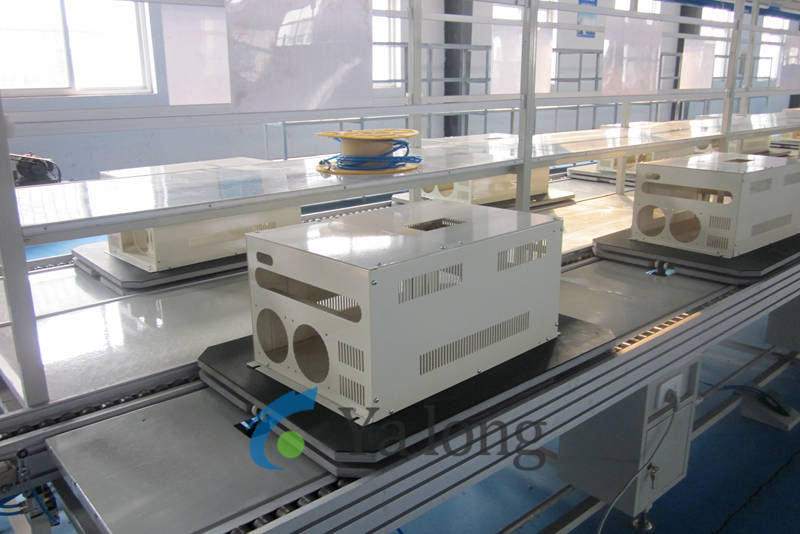

The inverter assembly line (production line) adopts a continuous belt conveyor line or a double-speed chain conveyor line to realize the automatic flow of semi-finished products or finished products between various stations to avoid stagnation and improve rhythm efficiency. Inverters are the core components of new energy power generation (photovoltaic, wind power), electric vehicle charging, and energy storage systems. This assembly line is suitable for the production of household/commercial inverters and energy storage converters (PCS) to meet distributed energy or grid energy storage needs.

In order to improve production efficiency and reduce human error, the inverter assembly line adopts an automated assembly line. Automated robotic arms and robots can quickly and accurately complete the placement, welding and fixing of components. The assembled inverter needs to undergo a series of functional tests, including the stability of input and output voltages and currents, as well as the efficiency and power curve of the inverter, to ensure that the product meets the design specifications. As a key component of the photovoltaic system, the inverter is crucial.

This inverter assembly line achieves efficient production from assembly to preliminary inspection through the combination of "automated transmission + manual precise control + intelligent monitoring". It combines precision, production capacity and quality control capabilities. Its design takes into account efficiency and safety, adapting to the strict requirements of inverter products for the reliability and electromagnetic compatibility (EMC) of electronic components.